The Intricacies of Nuclear Coils: Beyond the Atomic Frontiers

Leave a CommentNuclear coils refer to the components used in nuclear magnetic resonance (NMR) or magnetic resonance imaging (MRI) systems. They generate and detect radiofrequency (RF) signals that create images of the internal structures of biological or chemical samples. They are also arranged in specific configurations to optimize signal reception and spatial resolution.

This article will discuss the significance of a nuclear coil in NMR and MRI systems, exploring its role beyond atomic thresholds.

Design and Functionality of Nuclear Coils

A nuclear coil typically consists of conductive wire wound into a coil shape, often encased in a protective housing. Its design parameters number of windings, coil diameter, and construction material impact the sensitivity and resolution of the imaging system. As a result, engineers optimize them to achieve the best possible signal-to-noise ratio and spatial resolution in the resulting images.

Functionally, a nuclear coil has two primary purposes within an NMR or MRI system. First, it generates an RF magnetic field that interacts with the atomic nuclei in the imaged sample. This induces an apparent signal in the coil before processing it to create an image. Then, the same loop detects the resulting RF signal emitted by the sample.

The design and functionality of nuclear coils continue to evolve with advancements in technology and imaging techniques. Modern designs may incorporate advanced materials such as superconducting wires to improve sensitivity and reduce energy consumption. Additionally, engineers are exploring novel coil configurations and multi-channel arrays to enhance imaging speed and spatial resolution.

Unique Applications of a Nuclear Coil

Listed below are the unique applications of a nuclear coil:

Biomedical Research

Nuclear coils are often utilized in various biomedical research applications beyond clinical diagnostics, including studies of metabolism, physiology, and disease mechanisms. NMR spectroscopy techniques facilitated by these components enable researchers to probe biological samples, which provides valuable insights into processes and disease pathways.

Food and Agriculture

The food science and agriculture sectors often employ nuclear coils. They are mainly used for the quality control, authentication, and analysis of agricultural products and food additives. The coils guarantee food safety, determine nutritional content, and detect food contamination.

Forensic Analysis

A nuclear coil helps NMR techniques analyze trace evidence, identify chemical compounds, and elucidate crime scene details. It also enables forensic scientists to detect and quantify explosives, illicit drugs, and other substances in trace amounts. Moreover, it contributes to analyzing gunshot residue, fibers, and other physical evidence.

Geological Surveys

In geophysics and environmental science, nuclear magnetic resonance logging techniques utilize coils to characterize subsurface geological formations. Geoscientists can infer the porosity, permeability, and fluid content by analyzing the response of atomic nuclei in rocks to magnetic fields. This aids in mineral exploration, groundwater assessment, and environmental monitoring.

Material Characterization

NMR techniques use nuclear coils to characterize the characteristics of compounds in materials science and engineering. Researchers can assess material composition, phase transitions, and molecular dynamics by analyzing the interactions between atomic nuclei and external magnetic fields. This helps create new materials and technologies.

Petrophysics

Nuclear coils are frequently used in petrophysical tests to assess mineral characteristics in oil and gas reserves. They support nuclear magnetic resonance logging techniques in identifying reservoir rocks, determining fluid saturation, and assessing connectivity. In addition, they streamline the calculation of pore size distribution and permeability, which are crucial parameters for understanding reservoir behavior.

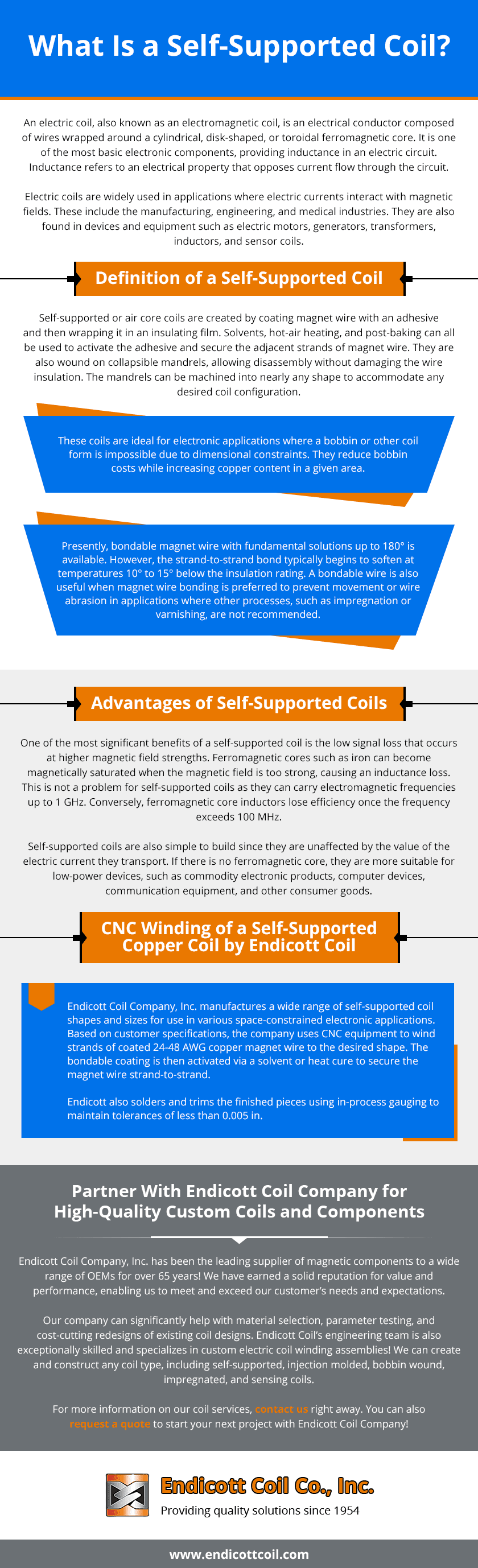

Endicott Coil Company: Your Reliable Source for High-Quality Coil Solutions

Are you looking for customized coil solutions? Endicott Coil Company is the place to go! We provide magnetic coils, transformers, solenoids, and other essential components to diverse industries and applications. Whether you require prototyped pieces or large-scale production solutions, our team is dedicated to delivering reliable and versatile products.

Contact us today for more details about our custom coil services, or request a quote!