Nuclear Sector

Precision-wound coils for the nuclear industry are engineered to deliver exceptional performance and durability in extreme conditions. Designed to withstand high temperatures, intense radiation, and strong magnetic fields, these coils are ideally suited for the most challenging nuclear environments.

Advanced techniques such as over-molding, potting, and varnishing are employed to provide maximum protection and ensure the longevity of each coil. These custom components are crucial for critical systems, including reactor control, radiation detection, and power generation. With a focus on reliability and robustness, our coils support the safe and efficient operation of essential nuclear technologies.

Relevant Applications

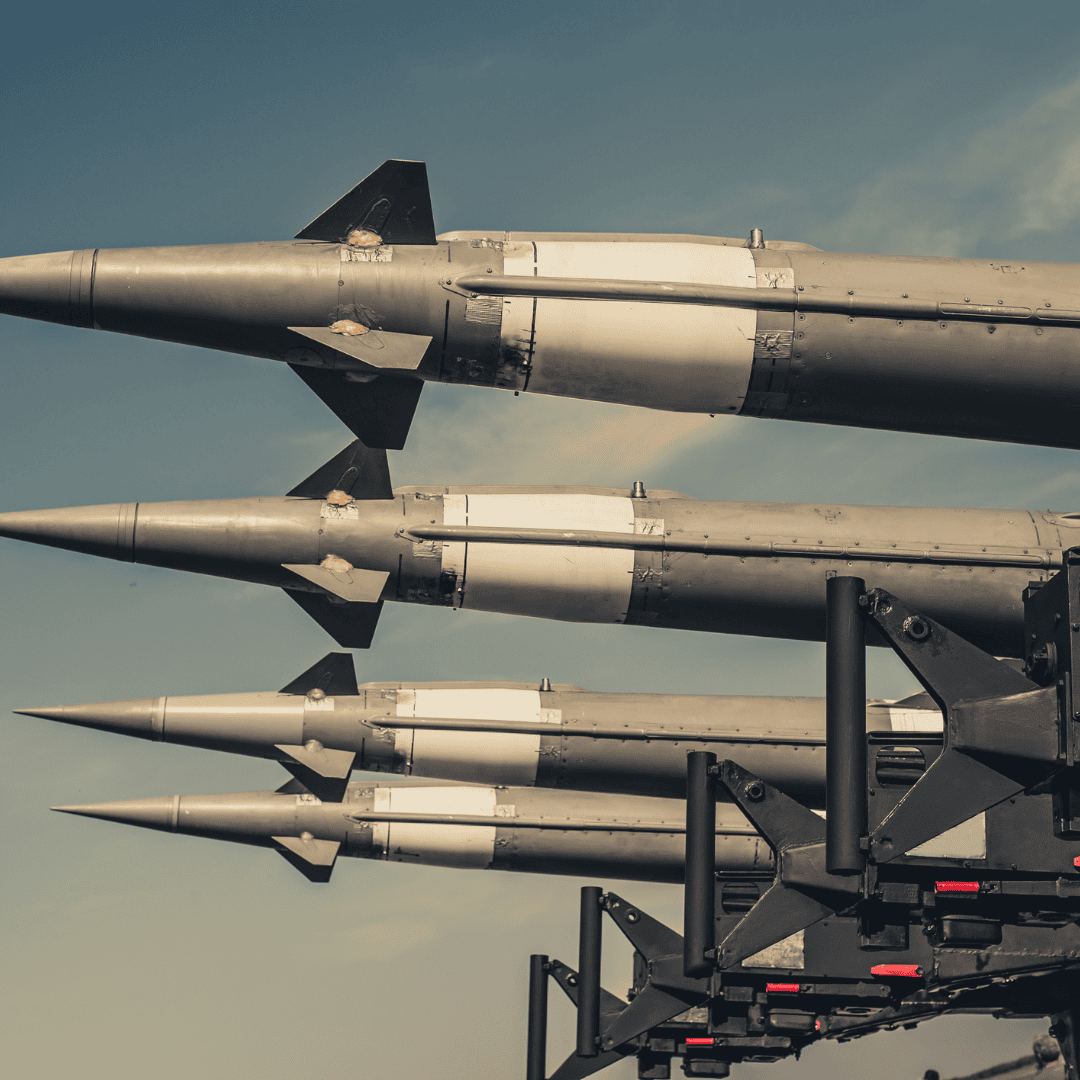

Missile Guidance Systems

Radiation Detection Equipment

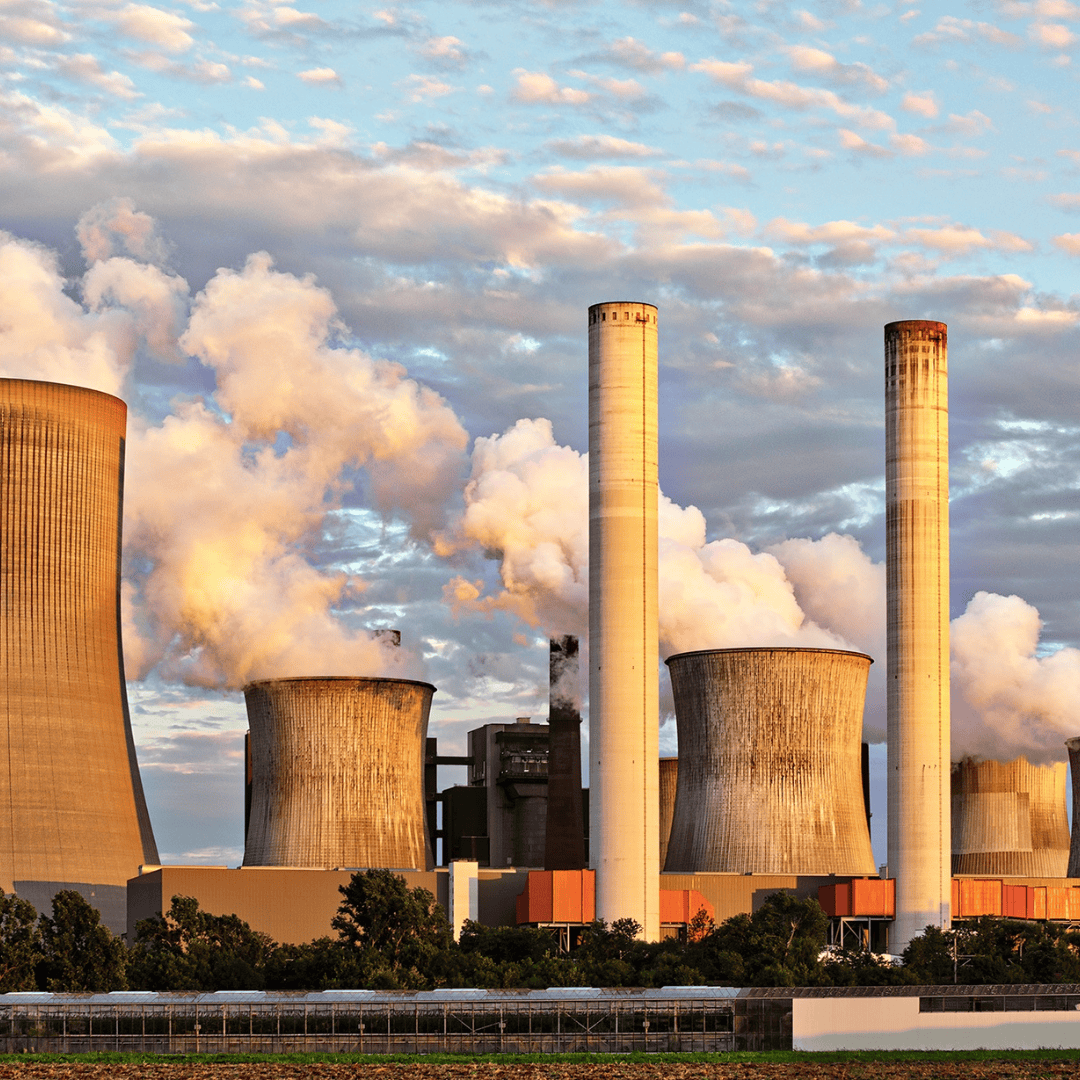

Power Generation Systems

Nuclear Propulsion Systems

Emergency Shutdown Systems

Neutron Flux Monitoring

Industry Highlights

At Endicott Coil Company, we craft precision-wound coils for the nuclear industry, engineered to thrive in demanding environments. Our high-density copper coils withstand extreme temperatures, radiation, and magnetic fields, with advanced over-molding and vacuum pressure impregnation ensuring maximum durability.

Our coils play a critical role in reactor control, radiation detection, and power generation. Through meticulous attention to detail and automated manufacturing, we deliver consistent quality and reliability. Though focused on non-safety-related components, our coils are essential for Control Rod Drive Mechanisms (CRDM) and recirculation systems, supporting efficient nuclear power generation.

Automated Precision Manufacturing

High-Density Copper Coils

Advanced Protection Techniques

Critical Components

Standards & Certifications

At Endicott Coil Co. we are dedicated to the highest manufacturing standards, providing assurance of quality and reliability in every coil. Our commitment to industry-leading practices is underscored by our certifications, reflecting our ongoing pursuit of excellence.

At Endicott Coil Co., we proudly hold the ISO 9001:2015 certification. This underscores our commitment to maintaining the highest standards of quality, ensuring that every coil we produce meets stringent international benchmarks for excellence.

Why Choose Us?

At Endicott Coil Co., we take pride in our distinctive approach that sets us apart from the competition.

We prioritize responsiveness and offer unparalleled technical support, adding significant value to our industrial coils.

Our commitment to a vertically integrated, in-house process ensures not only faster delivery but also superior technical assistance.

Experience

Legacy

Responsiveness

Support

Explore our blog on The Intricate Art of Coil Winding

How Precision Shapes Power

Coil winding involves the strategic arrangement of wire around a core to create coils, which are fundamental building blocks of various components. The process is a delicate balance between the precision of winding machines and the expertise of operators.

This article delves into the methods and tools that shape a coil’s efficiency and power-handling abilities. We’ll also talk about challenges during the winding process and the innovative solutions available.