An electromagnetic coil, also known as an electric coil is an electrical conductor containing a set of conductive wires wrapped around a specified shape and size. This can be a self-supporting (air core) design or include a customer specified core. Electrical coils are simple electronic components that provide inductance in an electromagnetic circuit. There are many coil types to meet the needs of various equipment. Electromagnetic coils can vary by wire gauge, length, coil diameter, core material, and other factors such as Overmolding.

Overmolding is a multi-step process where two or more components are molded over top of one another. Overmolded coils are protected from moisture, corrosive chemicals, vibration, explosions, and harsh working environments by being molded in a tough temperature resistant material.

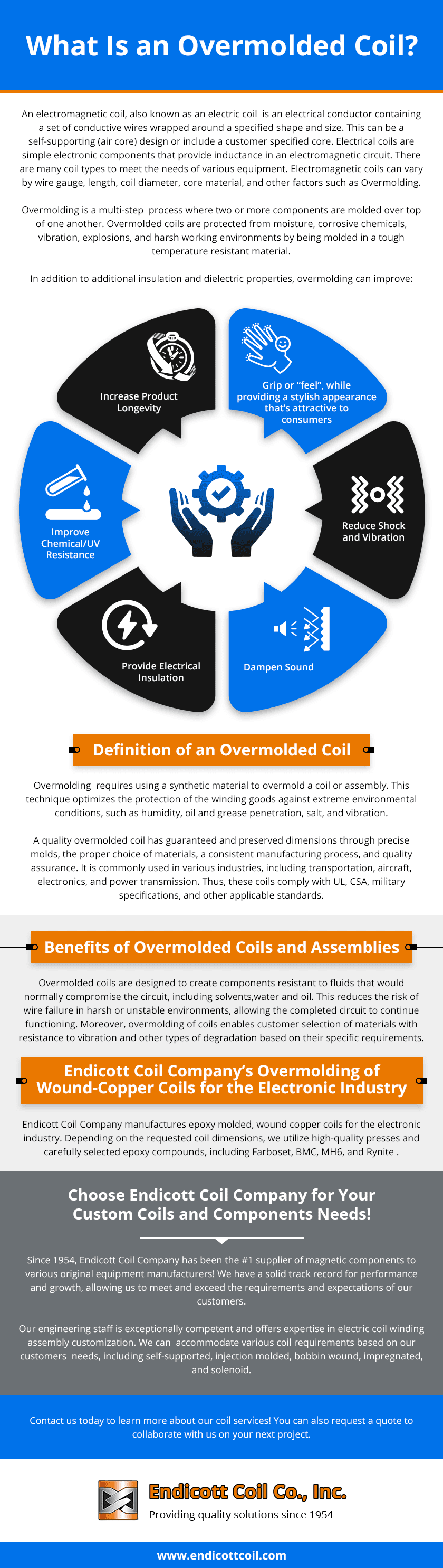

In addition to additional insulation and dielectric properties, overmolding can improve:

- Grip or “feel”, while providing a stylish appearance that’s attractive to consumers

- Reduce shock and vibration

- Dampen sound

- Provide electrical insulation

- Improve chemical/UV resistance

- Increase product longevity

Definition of an Overmolded Coil

Overmolding requires using a synthetic material to overmold a coil or assembly. This technique optimizes the protection of the winding goods against extreme environmental conditions, such as humidity, oil and grease penetration, salt, and vibration.

A quality overmolded coil has guaranteed and preserved dimensions through precise molds, the proper choice of materials, a consistent manufacturing process, and quality assurance. It is commonly used in various industries, including transportation, aircraft, electronics, and power transmission. Thus, these coils comply with UL, CSA, military specifications, and other applicable standards.

Benefits of Overmolded Coils and Assemblies

Overmolded coils are designed to create components resistant to fluids that would normally compromise the circuit, including solvents,water and oil. This reduces the risk of wire failure in harsh or unstable environments, allowing the completed circuit to continue functioning. Moreover, overmolding of coils enables customer selection of materials with resistance to vibration and other types of degradation based on their specific requirements.

Endicott Coil Company’s Overmolding of Wound-Copper Coils for the Electronic Industry

Endicott Coil Company manufactures epoxy molded, wound copper coils for the electronic industry. Depending on the requested coil dimensions, we utilize high-quality presses and carefully selected epoxy compounds, including Farboset, BMC, MH6, and Rynite .

Choose Endicott Coil Company for Your Custom Coils and Components Needs!

Since 1954, Endicott Coil Company has been the #1 supplier of magnetic components to various original equipment manufacturers! We have a solid track record for performance and growth, allowing us to meet and exceed the requirements and expectations of our customers.

Our engineering staff is exceptionally competent and offers expertise in electric coil winding assembly customization. We can accommodate various coil requirements based on our customers needs, including self-supported, injection molded, bobbin wound, impregnated, and solenoid.

Contact us today to learn more about our coil services! You can also request a quote to collaborate with us on your next project.