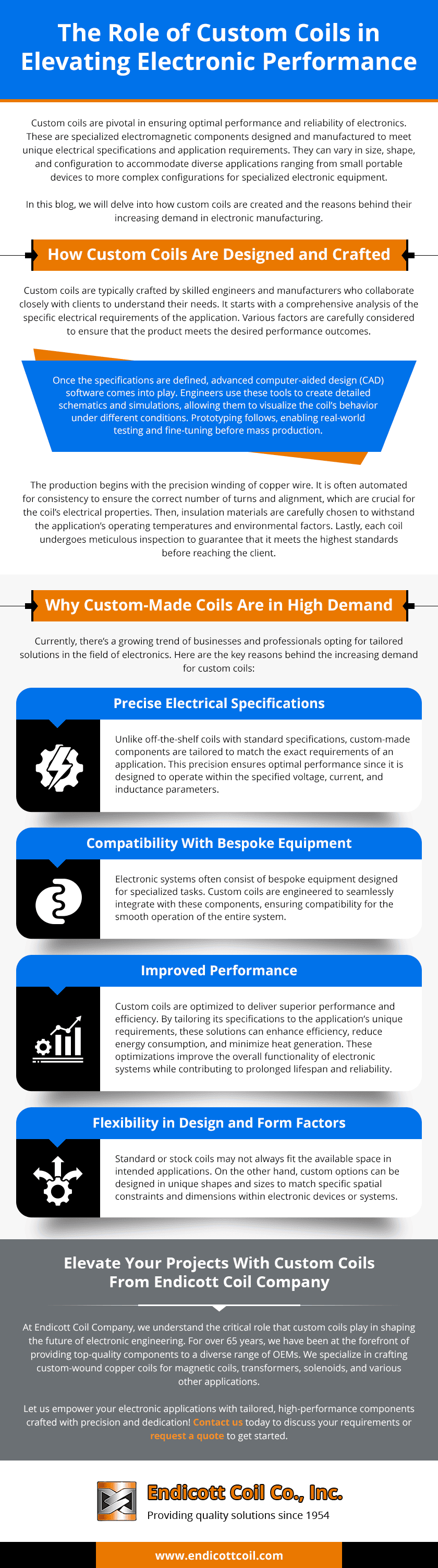

Custom coils are pivotal in ensuring optimal performance and reliability of electronics. These are specialized electromagnetic components designed and manufactured to meet unique electrical specifications and application requirements. They can vary in size, shape, and configuration to accommodate diverse applications ranging from small portable devices to more complex configurations for specialized electronic equipment.

In this blog, we will delve into how custom coils are created and the reasons behind their increasing demand in electronic manufacturing.

How Custom Coils Are Designed and Crafted

Custom coils are typically crafted by skilled engineers and manufacturers who collaborate closely with clients to understand their needs. It starts with a comprehensive analysis of the specific electrical requirements of the application. Various factors are carefully considered to ensure that the product meets the desired performance outcomes.

Once the specifications are defined, advanced computer-aided design (CAD) software comes into play. Engineers use these tools to create detailed schematics and simulations, allowing them to visualize the coil’s behavior under different conditions. Prototyping follows, enabling real-world testing and fine-tuning before mass production.

The production begins with the precision winding of copper wire. It is often automated for consistency to ensure the correct number of turns and alignment, which are crucial for the coil’s electrical properties. Then, insulation materials are carefully chosen to withstand the application’s operating temperatures and environmental factors. Lastly, each coil undergoes meticulous inspection to guarantee that it meets the highest standards before reaching the client.

Why Custom-Made Coils Are in High Demand

Currently, there’s a growing trend of businesses and professionals opting for tailored solutions in the field of electronics. Here are the key reasons behind the increasing demand for custom coils:

Precise Electrical Specifications

Unlike off-the-shelf coils with standard specifications, custom-made components are tailored to match the exact requirements of an application. This precision ensures optimal performance since it is designed to operate within the specified voltage, current, and inductance parameters.

Compatibility With Bespoke Equipment

Electronic systems often consist of bespoke equipment designed for specialized tasks. Custom coils are engineered to seamlessly integrate with these components, ensuring compatibility for the smooth operation of the entire system.

Improved Performance

Custom coils are optimized to deliver superior performance and efficiency. By tailoring its specifications to the application’s unique requirements, these solutions can enhance efficiency, reduce energy consumption, and minimize heat generation. These optimizations improve the overall functionality of electronic systems while contributing to prolonged lifespan and reliability.

Flexibility in Design and Form Factors

Standard or stock coils may not always fit the available space in intended applications. On the other hand, custom options can be designed in unique shapes and sizes to match specific spatial constraints and dimensions within electronic devices or systems.

Elevate Your Projects With Custom Coils From Endicott Coil Company

At Endicott Coil Company, we understand the critical role that custom coils play in shaping the future of electronic engineering. For over 65 years, we have been at the forefront of providing top-quality components to a diverse range of OEMs. We specialize in crafting custom-wound copper coils for magnetic coils, transformers, solenoids, and various other applications.

Let us empower your electronic applications with tailored, high-performance components crafted with precision and dedication! Contact us today to discuss your requirements or request a quote to get started.